Why India Needs Formal EV Battery Collection Networks — And How to Build Them

>

>

Why India Needs Formal EV Battery Collection Networks — And How to Build Them

India’s electric vehicle revolution is accelerating. With over 1.5 million EVs on our roads and projections suggesting exponential growth, we’re witnessing a historic transformation in mobility. Yet beneath this progress lies an urgent challenge that threatens to undermine our sustainability goals: what happens when these batteries reach end-of-life?

The answer today is deeply troubling. Despite our nation’s ambitious circular economy targets, a staggering 95–99% of end-of-life lithium-ion batteries never reach formal recycling channels. Instead, they disappear into India’s vast informal waste sector, processed by unregulated scrap dealers using rudimentary methods that pose serious environmental and safety risks.

At Nav Prakriti, we’ve spent years building state-of-the-art recycling infrastructure capable of recovering over 95% of critical materials from spent batteries. But we’ve learned a hard truth: world-class recycling facilities mean nothing if batteries never reach us. India’s missing link isn’t recycling capacity—it’s a formal collection network.

The Hidden Cost of Informal Processing

Walk through any major scrap market in India’s cities, and you’ll find lithium-ion batteries stacked alongside e-waste, often handled without basic safety protocols. Workers dismantle them manually, unaware of the residual electrical charge that can spark fires. The valuable materials inside—lithium, cobalt, nickel, manganese—are either crudely extracted or simply discarded.

The consequences ripple outward. Heavy metals leach into soil and groundwater. Communities near informal processing sites face contamination risks they didn’t choose. Fire hazards endanger workers and neighborhoods alike. And India loses access to critical raw materials we could be recovering and reusing in new batteries.

Perhaps most troubling is the complete absence of traceability. Once a battery enters the informal sector, it vanishes from any regulatory oversight. There’s no accountability, no environmental compliance, no worker safety standards. It’s a system built on invisibility—and it’s processing the vast majority of our end-of-life batteries.

Why Collection Networks Are the Foundation

Building recycling plants is relatively straightforward. Creating the logistics to consistently collect and transport hazardous waste across a country of 1.4 billion people? That’s the real challenge.

Effective battery collection requires coordinated infrastructure at multiple touchpoints. Vehicle dealerships and authorized service centers should serve as primary return points, where consumers can drop off old batteries when purchasing new vehicles or during routine maintenance. These locations already have established relationships with EV owners and the physical footprint to safely store batteries temporarily.

Dedicated collection points at vehicle scrapping facilities represent another critical node. As India’s vehicle scrappage policy gains momentum, end-of-life vehicles will increasingly flow through authorized centers—ideal locations for battery extraction and temporary storage before transport to recyclers.

But physical infrastructure alone isn’t enough. We need robust tracking systems—digital battery passports that follow each unit from manufacturing through multiple use-cycles to final recycling. Such systems would enable real-time monitoring of battery location, health status, and end-of-life processing, creating the transparency currently absent in informal channels.

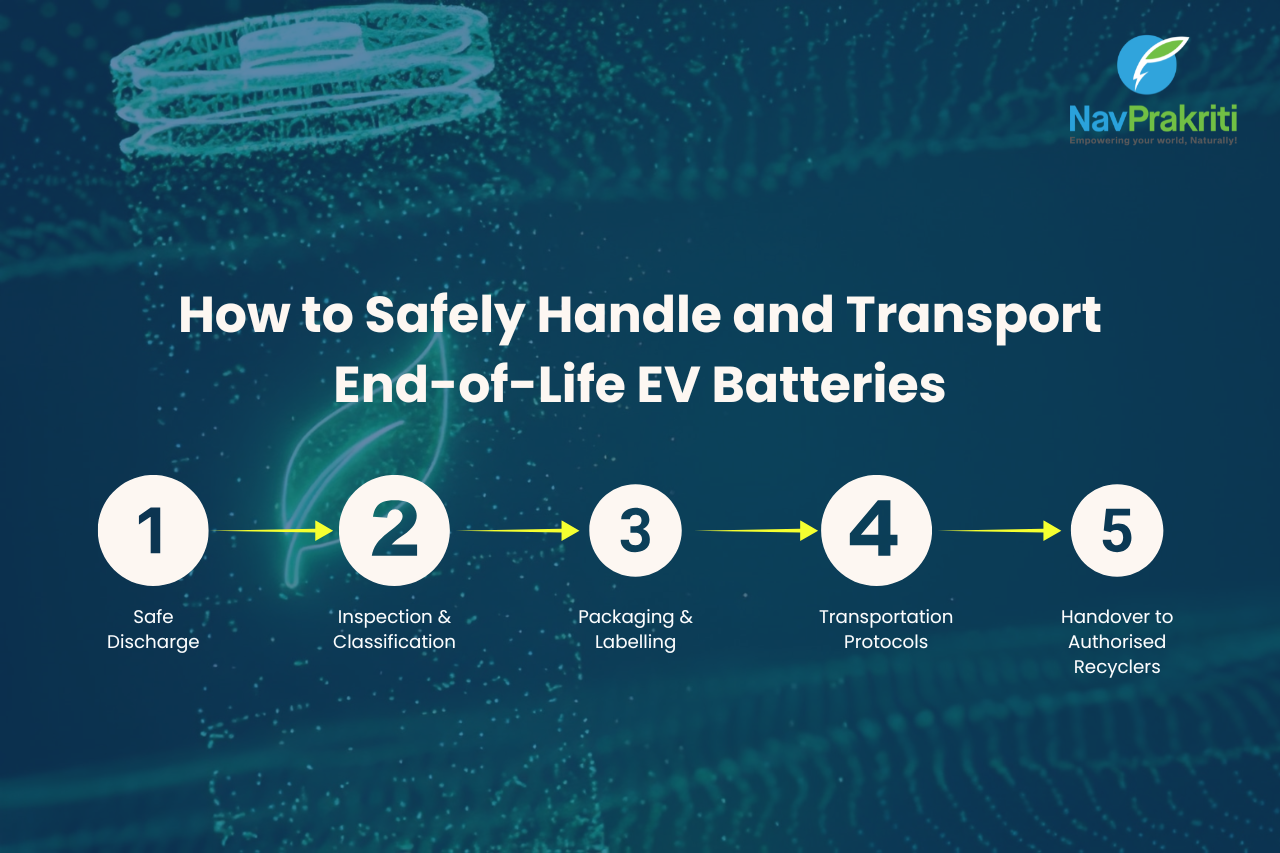

Safe transport protocols are equally essential. Lithium-ion batteries qualify as Class 9 dangerous goods under international shipping regulations. Moving them requires specialized containers, trained personnel, and compliance with transport safety standards. This isn’t work for ordinary logistics providers—it demands purpose-built capabilities.

A Proposed Framework: From Incentive to Infrastructure

Success requires coordinating multiple stakeholders—manufacturers, dealers, consumers, waste managers, transporters, and recyclers—around shared objectives. Here’s what an effective collection network might look like:

Incentivized Participation: Consumers should receive tangible benefits for returning batteries through formal channels. Deposit-refund schemes, where buyers pay a refundable fee at purchase and recover it upon proper disposal, have proven effective globally. Trade-in programs offering discounts on replacement batteries create similar motivation. The key is making formal recycling the easiest and most rewarding option.

Clear Responsibility Chains: Extended Producer Responsibility regulations must define specific collection and recycling obligations for every stakeholder. OEMs should manage collection from their authorized networks. Importers and sellers should establish take-back mechanisms. Third-party recyclers like Nav Prakriti should be certified and regularly audited for environmental compliance.

Digital Tracking Infrastructure: Battery passports—digital records containing manufacturing data, usage history, and end-of-life processing—should be mandatory for all EV batteries. Blockchain or cloud-based systems could provide tamper-proof tracking, enabling regulators to monitor compliance and quickly identify diversion into informal channels.

Specialized Transportation: Certified transport partners must handle the movement of end-of-life batteries from collection points to recycling facilities. This requires investment in appropriate containers, vehicle modifications, driver training, and insurance coverage—costs that should be factored into EPR compliance budgets.

Regional Collection Hubs: Rather than expecting every small dealer to arrange direct shipment to recyclers, regional aggregation centers could consolidate batteries from multiple collection points. These hubs would provide temporary storage, basic safety management, and economies of scale in transportation.

What Success Looks Like

Imagine India in 2030. An EV owner in Bangalore whose battery has degraded visits their dealer for replacement. The old battery is scanned, its digital passport updated, and it’s placed in a designated storage unit. Within weeks, it reaches Nav Prakriti’s facility, where advanced hydrometallurgical processes recover 96% of its materials. Those materials flow back into India’s battery manufacturing supply chain, reducing our import dependence and environmental footprint simultaneously.

In this future, informal processing becomes the exception rather than the rule. Recovery rates climb from today’s dismal 1–5% to 70% or higher within a decade. India’s dependence on imported lithium, cobalt, and nickel decreases as domestic recycling supplies a growing share of demand. Environmental contamination from improper disposal drops dramatically. Worker safety improves. And India demonstrates to the world that rapid EV adoption and environmental responsibility can coexist.

The Path Forward

At Nav Prakriti, we’re ready to process every battery that reaches us through formal channels. Our facilities meet international environmental standards. Our processes are optimized for maximum material recovery. We’re prepared to scale as volumes grow.

But we cannot do this alone. India needs urgent policy action to mandate collection infrastructure, enforce EPR compliance, and shut down informal processing. We need manufacturers to invest in take-back systems as enthusiastically as they invest in production. We need state governments to integrate battery collection into waste management planning. We need consumers to understand that how they dispose of batteries matters as much as choosing electric vehicles in the first place.

The technology exists. The regulations are taking shape. The business case is clear—recovered materials reduce production costs and import bills while generating green jobs. What’s missing is coordinated will to build the collection infrastructure that makes formal recycling inevitable rather than exceptional.

India’s EV future depends on solving this challenge. The batteries powering our clean mobility transition must themselves be managed sustainably from cradle to grave—or more accurately, from cradle to cradle. Formal collection networks are the essential foundation. It’s time we built them.

.png)

Leave a Reply